Technical Specification

| Item | TS100-1600 | |

|---|---|---|

| Print head | On-demand piezo head (2 staggered layout) | |

| Printing resolution | 360 dpi, 600 dpi, 720 dpi, 900 dpi | |

| Maximum drawing width | 1,610 mm (63 in) | |

| Media | Maximum width | 1,620 mm (64 in) |

| Thickness | 1 mm or lower | |

| Roll diameter | � mm or less | |

| Roll weight | 45 kg (99 lb) or less | |

| Ink set | 4C (BL,M,Y,K) | |

| Ink | Type | SB610 (BL,M,Y,K) |

| Capacity | 1000 ml bottle | |

| Interface | USB2.0 / Ethernet | |

| Power | Single-phase AC100-120V/AC200-240V±10% 50/60Hz±1Hz | |

| Power consumption | AC100V: 1,440W or less x1 / AC200V: 1,920W or less x1 | |

| Operational environment | Temperature: 20-30°C (68-86°F) Humidity: 35-65%Rh (without condensation) | |

| Dimensions (WxDxH) | 2,775 x 700 x 1,475 mm (109 x 28 x 58 in) | |

| Weight | 166 kg (366 lb) | |

| Item | Color | Item Code | Remark |

|---|---|---|---|

| Dye Sublimation Ink Sb610 | Blue | SB610-BLT-BA | 1000 ml bottle |

| Magenta | SB610-MT-BA | ||

| Yellow | SB610-YT-BA | ||

| Black | SB610-KT-BA | ||

| Flushing liquid 03 Bottle | - | FL003-Z-BA | 1L bottle |

| Flushing liquid 03 Cartridge | - | FL003-Z-22 | 220 ml cartridge |

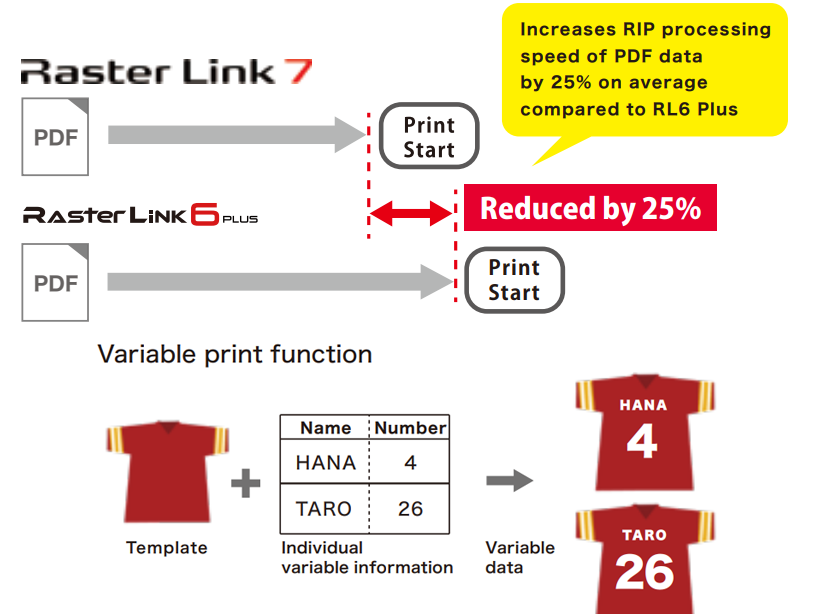

Combination of upgraded

usability and functionality

Increases RIP processing speed of PDF data

by 25% on average.

Improves reproducibility of PDF print data with special effects

Easy-to-check displays

Specifications settings on one screen

Displays pop-up window at an error

Improves reproducibility of PDF print data with special effects

Easy-to-check displays

Specifications settings on one screen

Displays pop-up window at an error

Providing for high productivity

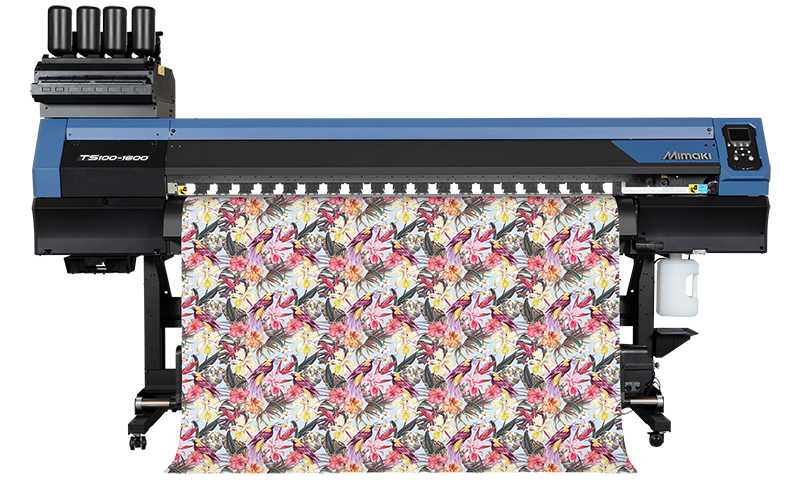

Low cost but very versatile printer which can apply to print the most common width of 1.6 m in the textile apparel industry. Remarkable model of the Mimaki dye sublimation transfer printer which realized approximately double print speed of conventional models.(*1)

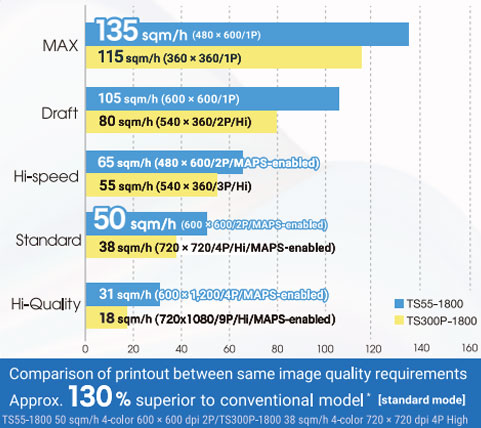

Print Speed

Double print speed approx. of conventional models !

Max.70 m/h of print speed!

It is a powerful model which realized the double print speed of that of our conventional textile printers. Necessary volume of printed textiles can be produced on demand, the unnecessary inventory can be eliminated. It can simplify the production site and production management, allowing you to focus on higher value-added jobs.

When compared to our previous models for textile apparel application :JV150-160 (equipped with water-based sublimation ink) and TS30-1300.

Common features of Mimaki "100 series" products for safety and stability.

It is the function to print a dedicated pattern to the media and read by the sensor mounted on the carriage to adjust automatically:

- Dot position (Dot jetting position at the bi-direction)

- Feeding amount (Media feeding amount)

Max.70 m/h of print speed!

It is a powerful model which realized the double print speed of that of our conventional textile printers. Necessary volume of printed textiles can be produced on demand, the unnecessary inventory can be eliminated. It can simplify the production site and production management, allowing you to focus on higher value-added jobs.

When compared to our previous models for textile apparel application :JV150-160 (equipped with water-based sublimation ink) and TS30-1300.

Common features of Mimaki "100 series" products for safety and stability.

It is the function to print a dedicated pattern to the media and read by the sensor mounted on the carriage to adjust automatically:

- Dot position (Dot jetting position at the bi-direction)

- Feeding amount (Media feeding amount)

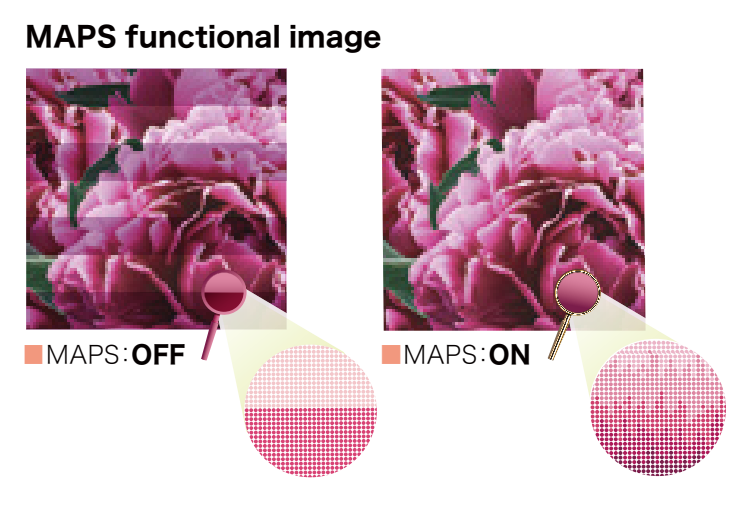

MAPS functionality reduces banding

In ordinary textile printers, the straight pass boundaries often results in bandings and discoloration due to slight misalignment. The "MAPS (Mimaki Advanced Pass System)" functionality provides gradation to printed pass boundaries and maintains stable print quality by reducing banding and uneven color.

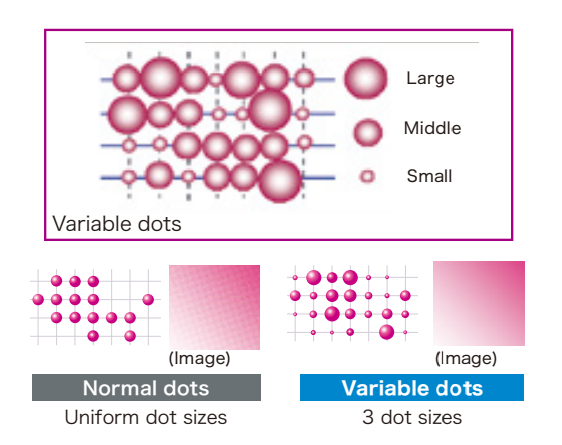

Minimum ink size 5pl Beautiful print of less granularity feeling

TS100-1600 can diffentiate to jet into 5/13/19 pl of 3 steps of droplet size. Three different ink drop sizes are enable to achieve high-quality prints with rich tonal range and fine expression with reduced granular feeling. The optimal drop size for each mode is embedded in profiles of the TS100-1600.

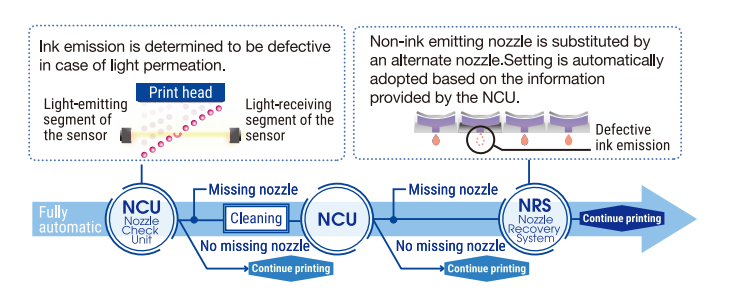

NCU/NRS employed to monitor missing nozzlesa

The sensor automatically detects the condition of nozzles. When the NCU (Nozzle Check Unit) detects a missing nozzle, it automatically performs cleaning. If there is a nozzle problem left unsolved by the cleaning, the NRS (Nozzle Recovery System) automatically replaces the defective nozzles with other nozzles, and enables users to continue their operation without waiting for service personnel. The NRS is supported from the one-pass printing to apply the fastest print mode.

Mimaki genuine dye sublimation ink Sb610

High-density ink that dramatically improves the beauty of prints on polyester materials

The high-density and fastness ink provides vivid colors and high color reproducibility which is suitable for fashion clothing, sports wear and soft signs etc.

It can be used for a wide range of products, from original items such as team wear, bags, and stage costumes to large-volume production. Since the Sb610 is excellent in its stability during the continuous discharging and also when left unattended for suspension of operation, it can output without stress, which greatly contributes to productivity at site.

New! 1000ml Bottle

Mimaki's dye sublimation ink using 1000ml bottles for the 1st time, reducing replacement frequency and cost.

The Sb610 dedicated to the environment and safety of products and production sites

The Sb610 has obtained the "ECO PASSPORT" certification as defined by the Oeko-Tex International Community based in Switzerland. "ECO PASSPORT certifies that the dyes and pigments used to color textile products, as well as the chemicals used to add functionality, do not contain harmful ingredients. This is a certification by a third-party organization that certifies the world's highest level of safety, which also complies with the European REACH regulation. We have led the industry in the development of inkjet printers and inks that reduce environmental impact.We will continue to strive to provide products and services that reduce environmental impact and are safe and secure, along with high quality printing technology.