Technical Specification

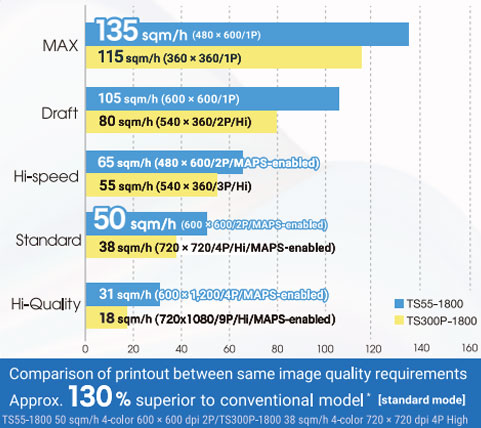

The "TS55-1800" is a revolutionary sublimation transfer inkjet printer for apparel/textile achieving high-speed printout of up to 135 sqm/h (1,453 sq.ft/h). superior functionality and convenient options suited for stable, long-term printout sessions at reduced cost.

Options aiming for cost reduction

Mini-jumbo roll unit corresponding to high-speed, high-volume demands.

This is a feeding unit to load the "Mimaki Vision Jet-X" transfer paper with a length of about 2,500 m (8,202 ft). It reduces the cost per square meter and shortens the downtime due to media replacement, when compared with the case using the previous 150 m (492 ft) -long transfer paper.

The mini-jumbo roll, "Mimaki Vision Jet-X" featuring approximately 2,500m (8,202 ft/h) of transfer paper is announced concurrently with model "T555-1800",

Previously using a transfer paper roll of 150m (492 ft) length to print at the maximum print speed (135 sqm/h; 1,453 sq.ft/h) of "T555-1800", it was incapable to have a continuous printing like all-night operation without operators fue to necessity of their paper replacing work. However the combination of the mini-jumbo roll, "Mimaki Vision Jet-X" and "T555-1800" allows for extended printout sessions unattended. The mini jumbo roll also contributes to reducing the running cost of printer systems with lower per-square meter unit price in comparison to smaller rolls. When using smaller 150 m rolls When using "Mimaki Vision Jet-X mini-jumbo rolls

The mini-jumbo roll, "Mimaki Vision Jet-X" featuring approximately 2,500m (8,202 ft/h) of transfer paper is announced concurrently with model "T555-1800",

Previously using a transfer paper roll of 150m (492 ft) length to print at the maximum print speed (135 sqm/h; 1,453 sq.ft/h) of "T555-1800", it was incapable to have a continuous printing like all-night operation without operators fue to necessity of their paper replacing work. However the combination of the mini-jumbo roll, "Mimaki Vision Jet-X" and "T555-1800" allows for extended printout sessions unattended. The mini jumbo roll also contributes to reducing the running cost of printer systems with lower per-square meter unit price in comparison to smaller rolls. When using smaller 150 m rolls When using "Mimaki Vision Jet-X mini-jumbo rolls

Extended heater supporting stable operation

The extended heater attached to the lower portion of the standard heater facilitates the drying of high-speed printing results.

10kg ink supply unit corresponding to extended successive printing jobs

Equipment of the large quantity of 10kg (22 lb) ink tank enables long-term suc cessive operations such as over-night printout sessions. The tank achieves si gnificant reductions in running cost and operation time over the standard 2 liter pack cartridges.

Providing for high productivity

Maximum printout speed mode 135 sqm/h (1,453 sq.ft/h) /Standard quality mode 50 sqm/h (538 sq.ft/h)

Adoption of the newly developed print heads ensures high-quality print even at a high speeds, achieving 130% productivity over our conventional model (TS300P-1800) with standard quality mode printing at 50 sqm/h (538 sq.ft/h). By newly enabling the use of "MAPS" function in high-speed mode (65sqm/h; 699 sq.ft/h) printing, TS55-1800 achieves excellent image quality even with high speed printing.

Technologies for uninterruptedreliable printing operations.

"MAPS" functionality reduces banding In ordinary textile printers, the straight pass boundaries often results in bandings and discoloration due to slight misalignment. The "MAPS (Mimaki Advanced Pass System) functionality provides gradation to printed pass boundaries and maintains stable print quality by reducing banding and uneven color.

Technologies for uninterruptedreliable printing operations.

"MAPS" functionality reduces banding In ordinary textile printers, the straight pass boundaries often results in bandings and discoloration due to slight misalignment. The "MAPS (Mimaki Advanced Pass System) functionality provides gradation to printed pass boundaries and maintains stable print quality by reducing banding and uneven color.

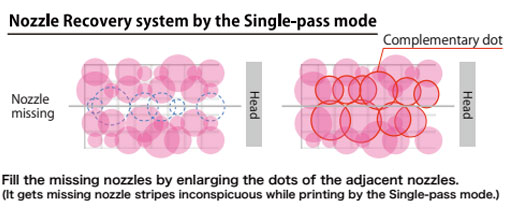

Minimization of NCU/NRS downtime

Incorporates Mimaki's unique automatic nozzle check unit ("NCU").

When the NCU detects a missing nozzle, it automatically performs cleaning to solve the problem. If the missing nozzle remains unresolved after cleaning, printing is commenced upon switching to an alternate nozzle. The print can be restarted to maintain productivity, without the need to wait for a service representative

The NRS is applied to the 1 Pass print mode, too. Even the max. print mode is very practical for the producion.

More user-friendliness!

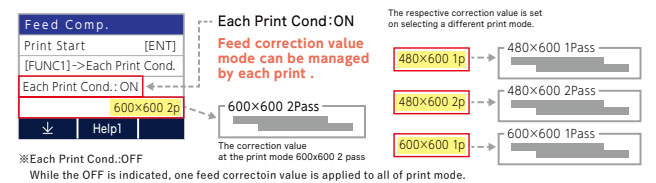

Feed correction function by print mode.

Different feed correction values can be applied to each print mode. Feed correction value for each print mode can be managed by machine setting. It is not necessary to perform feed confirmation for every mode and reduces the work of operator.

Different feed correction values can be applied to each print mode. Feed correction value for each print mode can be managed by machine setting. It is not necessary to perform feed confirmation for every mode and reduces the work of operator.

Technical Specification

Unit

| Print Head | Head Assy Stagger Layout |

|---|---|

| Print Resolution | 480 dpi, 600 dpi, 720 dpi, 1200 dpi |

| Maximum Print Width | 1,940 mm (76.4 in) |

| Maximum Media Width | 1,950 mm (76.8 in) |

| Rolled Media Weight | 45 kg (99.2 lb) |

| Ink Slot | 8 |

| Ink Set | 4c / 6c / 7c / 8c |

| Ink Type | Sb610 (BI / Y / M / K / LBl / Lm / Lk / Fy / Fp) |

| Ink Capacity | 2L Ink Pack / 10kg Ink Tank |

| Safety Standard | VCCI Class A, FCC Class A, CE Marking, EMC, RoHS, Energy Star, RCM, EAC |

| Interface | USB 2.0 Hi-Speed, Ethernet 1000BASE-T |

| Power | Single Phase AC 100-120 V / AC 200-240 V × 1 |

| Power Consumption | AC 100 V: 1.44 kW AC 200 V: 1.92 kW or less |

| Operational Environment | Temperature: 20-30°C (68-77°F) Humidity: 35-65% Rh (Non-condensing) |

| Dimensions (W × D × H) | 3,240 × 713 × 1,857 mm (127.6 × 28.1 × 73.1 in) |

| Weight | 202 kg (445.3 lb) |

Supply

| Item | Item Code | Description | |

|---|---|---|---|

|

Sublimation Transfer Ink (2L Ink Pack) - |

Blue | SB610-BLT-2L | |

| Yellow | SB610-YT-2L | ||

| Magenta | SB610-MT-2L | ||

| Black | SB610-KT-2L | ||

| Light Blue | SB610-LBT-2L | ||

| Light Magenta | SB610-LMT-2L | ||

| Light Black | SB610-LKT-2L | ||

| Fluorescent Yellow | SB610-FYT-2L | ||

| Fluorescent Pink | SB610-FPT-2L | ||

|

Sublimation Transfer Ink (10kg Ink Tank) - |

Blue | SB610-BLT-BJ | The option "10Kg Ink supply unit (OPT-J0475) is necessary to set. |

| Yellow | SB610-YT-BJ | ||

| Magenta | SB610-MT-BJ | ||

| Black | SB610-KT-BJ | ||

| Light Blue | SB610-LBT-BJ | ||

| Light Magenta | SB610-LMT-BJ | ||

| Flushing Liquid 03 Cartridge | FL00 3 Z 22 | 220ml Cartridge | |

| Flushing Liquid 03 2L Pack | FL00 3 Z L2 | ||

Option

| Mini-Jumbo Roll Unit Specifications | |

| Item | Mini-Jumbo Roll Unit |

|---|---|

| Max. Weight | Winding 100 kg (220.5 lb) / Feeding 300 kg (661.4 lb) |

| Max. Diameter | Winding 280 mm (11 in) / Feeding 600 mm (23.6 in) |

| Max. Width | 1,910 mm (75.2 in) |

| Max. Printable Width | 1,900 mm (74.8 in) |

| Power | Single phase AC 200-240V × 1 |

| Power Consumption | (AC 200V) 1.0 kW or less |

| Outside Dimensions (W × D × H) | 2,773 × 998 × 602 mm (109.1 × 39.3 × 23.7 in) (unit only) |

| Weight | 191 kg (421.1 lb) |

10KG Ink Supply Unit

| 10kg Ink Supply Unit Specifications | |

| Item | 10kg Ink Supply Unit |

|---|---|

| Item Code | OPT-J0475 |

| Ink Set | 4-colors / 6-colors / 7-colors / 8-colors |

| Ink | Type/Color: Sb610 (Bl/M/Y/K/Lbl/Lm/Lk/Fy/Fp) |

| Capacity: 10 kg ink tank (Per color) Lk, Fy, and Fp are supplied by 2L pack | |

| Outside Dimensions (W × D × H) | 824 × 1,035 × 383 mm (32.4 × 40.7 × 15.0 in) |

| Weight | 35 kg (77.2 lb) |

Extended Heater

| Extended Heater Specifications | |

| Item | Extended Heater |

|---|---|

| Item Code | OPT-J0481 |

| Power | Single phase AC100-120V / AC200-240V ±10% 50/60Hz ±1Hz |

| Power Consumption | (AC 100 V) 1.0 kW or less / (AC 200 V) 1.0 kW or less |

| Outside Dimensions (W × D × H) | 2,336 × 108 × 236 mm (91.9 × 4.2 × 9.2 in) |

| Weight | 15 kg (33.1 lb) |