Technical Specification

Raster Link 7

Combination of upgraded usability and functionality

Improves reproducibility of special effects (such as transparency) of PDF data

Increases RIP processing speed of PDF data by 25% on average

Prints out the variable data by Variable print function

Displays frequently used setting and pop-up windows

TxLink 4

Parallel RIP improving production efficiency

16-bit rendering for smoother gradation expression

Fluorescent inks as a complementary color of process colors

to achieve vivid color reproduction

Possible to add logos, seam allowance and barcode etc. by

Image add-on function

| Item | TS100-1600 | |

|---|---|---|

| Print head | On-demand piezo head (2 staggered layout) | |

| Printing resolution | 300, 600, 900, 1200 dpi | |

| Maximum drawing width | 1,610 mm (63.4 in) | |

| Media | Maximum width | 1,620 mm (63.8 in) |

| Roll diameter | φ250 mm (9.8 in) or less | |

| Roll weight | 45 kg (99.2 lb) or less | |

| Roll weight | 2/3 in | |

| Ink set | 4/6/7/8 C | |

| Ink | Type Color | Sb411 (Bl, M, Y, K, Lbl, Lm, Lk) Sb410 (Fy, Fp) |

| Ink Capacity | 2 L ink pack / 10 kg ink tank | |

| Print Gap | Manual adjustment by 3 levels (3.0/3.5/4.0 mm) | |

| Interface | Ethernet 1000 BASE-T / (USB2.0 High-speed) | |

| Power | Single phase AC100-120/200-240V±10% 50/60Hz±1Hz | |

| Power consumption | AC100V: 1,440W or less x1 / AC200V: 1,920W or less x1 | |

| Operational environment | Main unit: Max. 1,440 W or less Standard: 800 W | |

| Dimensions (WxDxH) | 3,170 × 820 × 1,305 mm (124.8 × 32.3 × 51.4 in) | |

| Weight | 240 kg (529.1 lb) | |

Supplies

| Item |

Code |

Remark | |

|---|---|---|---|

| Dye sublimation (transfer) ink* Sb411 2L ink pack ECO PASSPORT certified ink | Blue | - SB411-BLT-2L | |

| Magenta - | SB411-MT-2L | ||

| Yellow - | SB411-YT-2L | ||

| Black - | SB411-KT-2L | ||

| Light Blue - | SB411-LBT-2L | ||

| Light Magenta - | SB411-LMT-2L | ||

| Light Black - | SB411-LKT-2L | ||

| Fluorescent Yellow - | SB410-FPT-2L | ||

| Fluorescent Pink - | SB410-FYT-2L | ||

| Dye sublimation (transfer) ink* Sb411 10 kg ink tank ECO PASSPORT certified ink | Blue - | TBD | Supported later |

| Magenta - | TBD | ||

| Yellow - | TBD | ||

| Black - | TBD | ||

| Flushing liquid 03 220 ml | FL003-Z-22 | Flushing liquid for head cleaning | |

| Flushing liquid 03 2 L | FL003-Z-2L | Flushing liquid for ink replacement | |

| Item | Code |

| 10 kg ink tank supply unit | OPT-J0529 |

| Mini Jumbo roll unit for TS330 | TS330 Mini Jumbo roll unit |

| Small relay box | OPT-J0370 |

| Relay box2 | OPT-J0407 |

Give Your Creativity A Glow Up

Designed for textiles and apparel printing, TS330-1600 is a water-based dye

sublimation inkjet printer achieving superb productivity of 69m2

/h in Draft mode

and high image quality through Mimaki printing technology. Additionally, the

printer incorporates improved conveyance mechanism and renewed usability,

enabling stable and constant high quality printing.

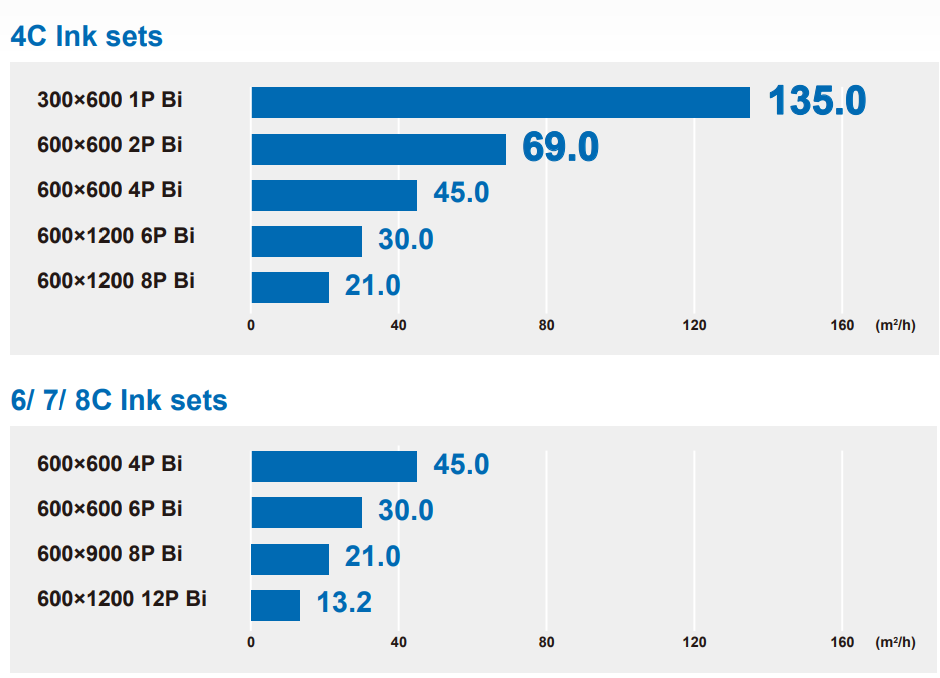

01 Achieving high productivity / high image quality

38% faster printing speed than a conventional model in Draft mode! *1

"Maximum speed mode: 135m ^ 2 / h Draft mode: 69m ^ 2 /h^ prime prime

Even in Draft mode, the output speed is approximately 1.3 times faster than conventional Mimaki printers, and the excellent printing technology enables even and uniform output of dark color prints during low passes. TS330-1600 combines high production and high quality to provide the printing quality meeting the requirements of the textile market.

1: Comparison TS330-1600 (print speed 69m ^ 2 / h : 600 * 600 dpi 2P Bi) and TS55-1800 (print speed * 50m ^ 2 / h 600 * 600 dpi 2P) at equivalent image quality

Introduction of new ink dispensing technology for high image quality

New Drop Technology, the "Mimaki Weaving Dot Technology"

A new ejection control technology reducing the unevenness and smearing of the ink, achieving higher image quality, with better solid coloring and smoother images than ever before

"Maximum speed mode: 135m ^ 2 / h Draft mode: 69m ^ 2 /h^ prime prime

Even in Draft mode, the output speed is approximately 1.3 times faster than conventional Mimaki printers, and the excellent printing technology enables even and uniform output of dark color prints during low passes. TS330-1600 combines high production and high quality to provide the printing quality meeting the requirements of the textile market.

1: Comparison TS330-1600 (print speed 69m ^ 2 / h : 600 * 600 dpi 2P Bi) and TS55-1800 (print speed * 50m ^ 2 / h 600 * 600 dpi 2P) at equivalent image quality

Introduction of new ink dispensing technology for high image quality

New Drop Technology, the "Mimaki Weaving Dot Technology"

A new ejection control technology reducing the unevenness and smearing of the ink, achieving higher image quality, with better solid coloring and smoother images than ever before

10kg ink-tank supply unit

10kg Sb411 ink (B/M/Y/K) ink-tanks newly available. Enables long period continuous output, such as in all night operations by mounting replace-ment ink-tanks on the optional 10kg ink-tank supply unit (sold separately). The tank achieves sígníficant reductions in running cost and operation time over the standard 2 liter packs.

*2: Lbl/Lm/Lk/Fy/Fp inks are available only in 2L ink-packs and can be used in parallel with the 10kg ink-tanks.

Mini jumbo roll unit

The use of long mini jumbo roll transfer paper*3

can further reduce running costs.

This reduces the downtime for media replacement as well as the burden on operators.

*3: Mimaki genuine media "Mini Jumbo Roll Mimaki Vision™™™ Jet-X Mini-162" (Supplied by Neenah Coldenhove) Specifications: width 1,620mm, roll length 2,500m, basis weight 57g/m²

*3: Mimaki genuine media "Mini Jumbo Roll Mimaki Vision™™™ Jet-X Mini-162" (Supplied by Neenah Coldenhove) Specifications: width 1,620mm, roll length 2,500m, basis weight 57g/m²

Mimaki print core technology for stable operation and stable image quality

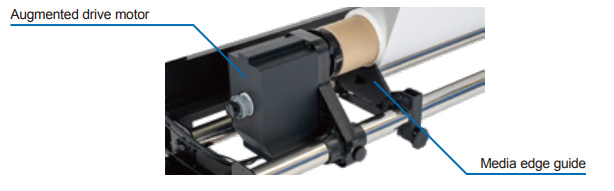

Stable operation by new conveyance mechanism with renewed conveyance control

Take-up device

Drive motors for the take-up device are mounted on both

left and right sides. This arrangement distributes the load

of wind-up, improving the winding stability, along with a

renewed mechanism to reduce media meandering.

Media edge guide

By aligning the edge of the media to the guide, it

prevents the media from meandering during winding

and ensures stable feeding. The small size improved

to an easy attachment/remove to/from paper core

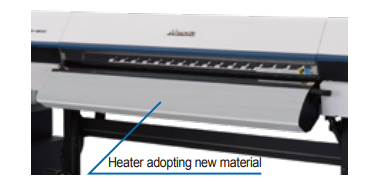

Post-heater

High durability materials are used for the post

heater to reduce abrasion caused by the transfer

paper feeding, preventing transfer paper feeding

failures to ensure stable printing.

Inheritance of Mimaki print core technology supporting stable operation and pursuing beauty in print.

DAS (Dot Adjustment System)

The printer automatically adjusts and optimizes the dot positioning and feed volume affecting print quality, corresponding to changes in the target media and printing conditions.

Waveform Control

Sophisticated ink ejection control unique to Mimaki printers ejects near-spherical droplets of ink for sharp expression of text, ruled lines and edges.

MAPS4 (Mimaki Advanced Pass System4)

Automatic optimal pattern selection according to printing conditions reduces banding and unevenness of color by introducing gradations to borders of passes while printing.

Variable Dot Control

Three different ink drop sizes, including a minimum drop quantity of 4pl, are intermingled to achieve smooth, high-quality prints with minimal graininess.

NCU/NRS

A sensor detects nozzle conditions and cleans them automatically. When nozzle clogging cannot be resolved, alternate nozzles are used to continue printing without slowing down

DAS (Dot Adjustment System)

The printer automatically adjusts and optimizes the dot positioning and feed volume affecting print quality, corresponding to changes in the target media and printing conditions.

Waveform Control

Sophisticated ink ejection control unique to Mimaki printers ejects near-spherical droplets of ink for sharp expression of text, ruled lines and edges.

MAPS4 (Mimaki Advanced Pass System4)

Automatic optimal pattern selection according to printing conditions reduces banding and unevenness of color by introducing gradations to borders of passes while printing.

Variable Dot Control

Three different ink drop sizes, including a minimum drop quantity of 4pl, are intermingled to achieve smooth, high-quality prints with minimal graininess.

NCU/NRS

A sensor detects nozzle conditions and cleans them automatically. When nozzle clogging cannot be resolved, alternate nozzles are used to continue printing without slowing down

Enhanced user friendliness

New functions for daily maintenance and remote operation have been added to enhance the convenience of operation

Featuring a new cleaning mechanism improving maintainability while reducing downtime, and a V-shaped cutting function improving media transportability.

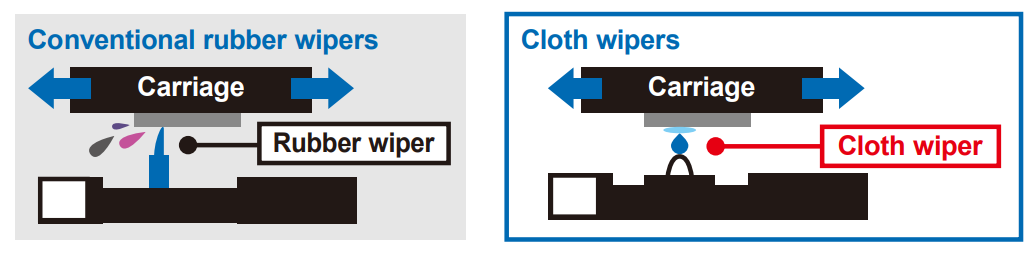

Introduction of cloth wiper - Improved removal performance for thick adhesive clots on the nozzle surface Designed to soak up ink from the nozzle surface, cloth wipers reduce the amount of ink splattered on the head station when compared to conventional rubber wipers. This reduces the frequency of maintenance around the head and cap and makes work easier

Easy-to-use maintenance space

A larger space for head maintenance making daily care easier, helps keeping the machine in optimum condition

New functions for daily maintenance and remote operation have been added to enhance the convenience of operation

Featuring a new cleaning mechanism improving maintainability while reducing downtime, and a V-shaped cutting function improving media transportability.

Introduction of cloth wiper - Improved removal performance for thick adhesive clots on the nozzle surface Designed to soak up ink from the nozzle surface, cloth wipers reduce the amount of ink splattered on the head station when compared to conventional rubber wipers. This reduces the frequency of maintenance around the head and cap and makes work easier

Easy-to-use maintenance space

A larger space for head maintenance making daily care easier, helps keeping the machine in optimum condition

Enhanced user friendliness

New functions for daily maintenance and remote operation have been added to enhance the convenience of operation

Featuring a new cleaning mechanism improving maintainability while reducing downtime, and a V-shaped cutting function improving media transportability.

Introduction of cloth wiper - Improved removal performance for thick adhesive clots on the nozzle surface Designed to soak up ink from the nozzle surface, cloth wipers reduce the amount of ink splattered on the head station when compared to conventional rubber wipers. This reduces the frequency of maintenance around the head and cap and makes work easier

Easy-to-use maintenance space

A larger space for head maintenance making daily care easier, helps keeping the machine in optimum condition

New functions for daily maintenance and remote operation have been added to enhance the convenience of operation

Featuring a new cleaning mechanism improving maintainability while reducing downtime, and a V-shaped cutting function improving media transportability.

Introduction of cloth wiper - Improved removal performance for thick adhesive clots on the nozzle surface Designed to soak up ink from the nozzle surface, cloth wipers reduce the amount of ink splattered on the head station when compared to conventional rubber wipers. This reduces the frequency of maintenance around the head and cap and makes work easier

Easy-to-use maintenance space

A larger space for head maintenance making daily care easier, helps keeping the machine in optimum condition

Automatic media cutting "V-shape cutting function"

The V-shape cutting function tapers the media into a V-shape before wrapping it around the paper core. You can choose between the conventional cutting method and the V-shape cutting method on the selection screen. The V-shape allows the center of the media to be precisely attached to the paper core, reducing the potential for human error. Applying V-shaped cuts to unused odd ends of the media for single point of attachment also helps to conserve the media.

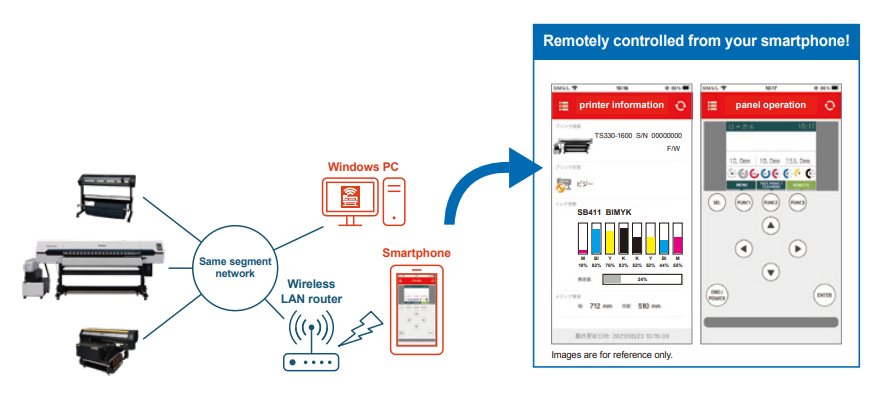

MRA (Mimaki Remote Access) - Enables printer operation via smartphones

The application allows you to monitor the status of the machine and operate the panel from a remote location within a same-segment network. You can check the list of ink types, heater temperature, notification alerts, etc. from your smartphone and operate the machine with the same feeling as the actual operation panel. *4 You can also turn on the heater of the machine before going to the job site, or output nozzle check patterns in advance.

The V-shape cutting function tapers the media into a V-shape before wrapping it around the paper core. You can choose between the conventional cutting method and the V-shape cutting method on the selection screen. The V-shape allows the center of the media to be precisely attached to the paper core, reducing the potential for human error. Applying V-shaped cuts to unused odd ends of the media for single point of attachment also helps to conserve the media.

MRA (Mimaki Remote Access) - Enables printer operation via smartphones

The application allows you to monitor the status of the machine and operate the panel from a remote location within a same-segment network. You can check the list of ink types, heater temperature, notification alerts, etc. from your smartphone and operate the machine with the same feeling as the actual operation panel. *4 You can also turn on the heater of the machine before going to the job site, or output nozzle check patterns in advance.